Restoring perfect rail alignment

Chockfast® project for the 1st European galvanizing plant in Belgium

How to restore perfect alignment of coil feed rails in record time?

We see every project as a challenge, a new opportunity to help our customers find the perfect shimming and sealing solution. Here’s a collaboration that’s been brilliantly realized!

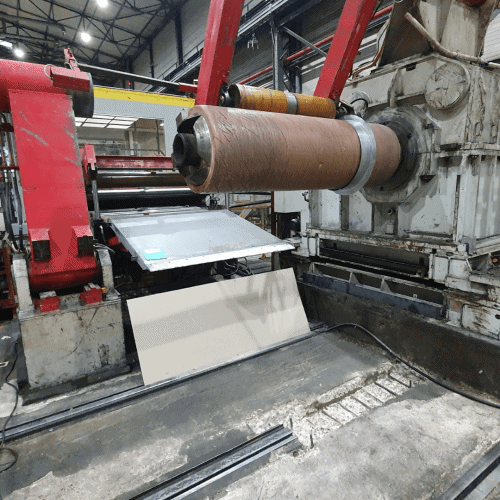

The challenge

The machine can only be stopped for a maximum of 36 hours. Labs of time during which we had to plan the complete dismantling of the existing rail, reassembly, perfect alignment and sealing. Even though we’re used to working in record time, it was essential to put in place a precise action plan, anticipating any unforeseen circumstances, and to work hand in hand with the various parties involved.

The Finres SA proposal

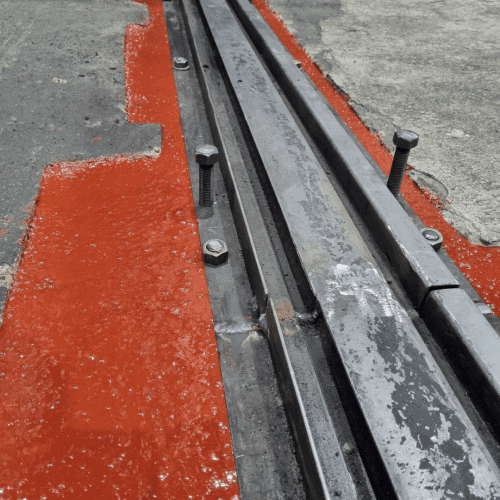

In terms of the product used, we proposed working with Chockfast ® Red as it ensures perfect alignment and adequate resistance to any oil and grease leaks from the coil feeder.

The realization

Finres was involved in the entire project process. Determining work procedures and schedules, and coordinating with the mechanical team. Efficient collaboration for optimum results.

A huge thank you to Georges Philippet, Mechanical Maintenance Manager at Segal, for his confidence and his testimonial:

“Following a request from SEGAL to repair the seat of a rail coil forklift truck (30 ton capacity), we agreed with Mr. Scheppers on a plan of action to meet the requirements of the specifications.

After the SEGAL purchase process, FINRES was ready to start the necessary actions according to the production schedule.

On D-day, the FINRES and SEGAL teams worked together to meet the deadline.

Following this joint intervention, we were able to test the operation of the said loading cart and conclude that the work carried out was a good job.

If in the future I’m consulted for a similar job, I’ll gladly recommend FINRES for its competence, professionalism and availability.”

Do you have a question about a similar project? Don’t hesitate to contact us, we’ll be happy to help.